A look at the new paint job on FLYING contributor Les Abend’s Piper Arrow. [Courtesy: Les Abend]

Who doesn’t love that new car smell? And if it’s in an airplane, even better. When George Mitri and his wife, Debbie, of Sky Comforts (www.skycomforts.com) presented me with the finished product of their hard work on the interior of our Piper Arrow, my first reaction was a gleaming smile. The fragrance of new leather that wafted out the open cockpit door was intoxicating. But more on that later.

When the airplane was first purchased seven and a half years ago, the exterior paint condition and design was a little dated.

If you're not already a subscriber, what are you waiting for? Subscribe today to get the issue as soon as it is released in either Print or Digital formats.

Subscribe NowTongue-in-cheek, I told my wife that she would still look good in the airplane regardless. That remark garnered an eye roll, as many of my airplane-related costs often do. At that time, a complete paint do-over was not on my radar, well…maybe further out at the 200 nm range.

For those who have followed the Jumpseat column over the last few years, you probably recall my wing story of woe. As a recap, my A&P friend discovered a suspicious skin flex and squeak on the upper side of the right wing just above the landing gear. He deemed the repair from a previous hard landing before my purchase inadequate. It rendered the airplane unairworthy.

Fortunately, I had turned my pre-buy inspection of the Arrow into an annual inspection. Much to its dismay, the shop that had performed the annual had signed the logbook with a satisfactory grade. Left unsaid, the shop knew its liability position. A negotiation process ensued, with the seller, broker, and shop agreeing to purchase and deliver a salvage wing to my previous airport home in Danbury, Connecticut (KDXR).

The salvage wing was in superior shape. No corrosion. No dents. And the salvage yard had shipped the wing from California with the fuel tank, which became a blessing. Even though the airplane with the wing that had been removed was only two serial numbers apart from ours, the fuel tank’s attachment screw holes didn’t align. Who woulda thought?

I elected not to push for the reimbursement of labor costs to remove and replace the wing, theorizing that the alternative in attorney’s fees would have been far greater. Unfortunately, the additional labor expense didn’t bolster my negotiating position with my wife for what I was about to justify. Once it was installed, the replacement wing stuck out like a sore thumb. It was void of any design, or any personality for that matter.

The airplane had become Frankenstein…at least in my eyes. So, the options were to ignore the wing or paint it to match, or…. Well, I’m certain my fellow airplane owners know the last option. Yup, paint the entire airplane.

The justification process seemed totally rational. Why spend the money to just match an outdated design? Might as well go all-in. I soon became the recipient of a double eye roll. It didn’t get much better when I gave my wife an estimate north of $20,000. The final invoice was higher because of the fuel tank refurbishment and other assorted plastic replacement parts, etc. I incentivized the project further by enticing my wife that a new registration with a personalized N-number was in her future. I did get a meager smile, but only because she felt sorry for my lame attempt at rationalizing.

In the end, I was able to convince my favorite copilot. Most likely, she knew that the project was inevitable. At that time, I was still gainfully employed as a Boeing 777 captain, so our starvation was not likely. The finished product was beautiful. The airplane still looks as though it just rolled out of the paint shop. Which brings me to the next project.

The airplane interior had been an 8 out of 10 when it was purchased, but it wasn’t the best of quality. The pilot seats were leather-ish with moderate comfort. The aft seats were fabric and showing signs of wear. The carpet, especially up front, was displaying the fatigue of being trampled by feet and leaked on by hydraulic fluid from the toe brakes. The fabric and vinyl side panels were aging at the same rate as my gray hair.

The plastic trim was cracking and yellowing in places. And the instrument panel brought back memories of my days flying Pipers at Purdue University…just after Amelia Earhart had been around campus I believe. I had already set the groundwork for refurbishing the interior by allocating some of my liquid retirement funds. In other words, it was already on the radar. But we unexpectedly jumped into retirement, building a house, and all the other expenses associated with such ventures. The airplane interior went to the bottom of the priority wish list.

By the time our finances were in a comfortable place, my wife had been subjected to periodic snippets of the interior redesign. I enticed her with the idea of more lumbar support and an extended bottom cushion for thigh support.

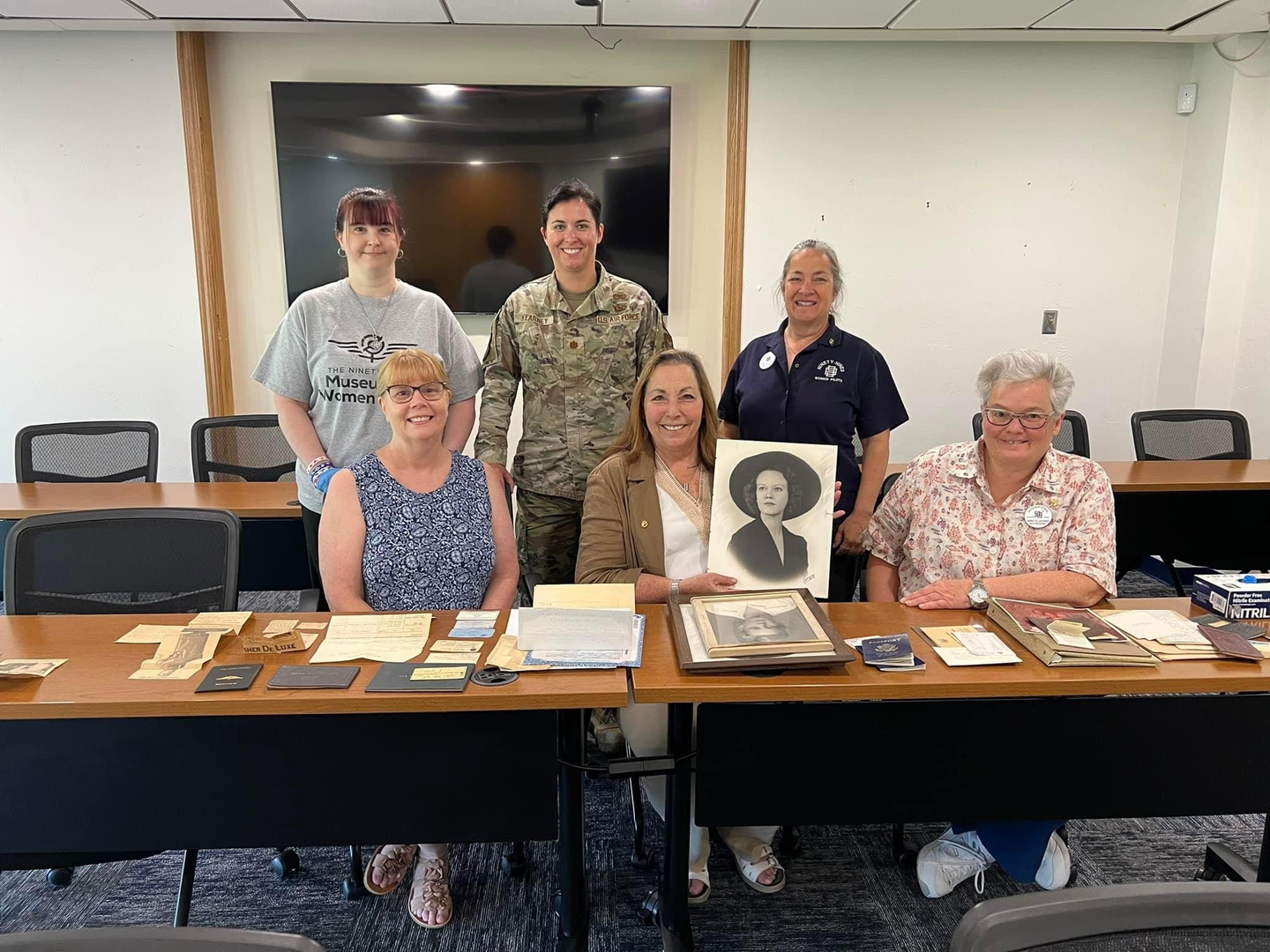

The search for a reputable airplane interior shop was becoming frustrating, however. But fate intervened. While George Mitri was looking for contact info to reconnect with me for other reasons, I discovered his old company listed in a Pipers Source Guide magazine. Mitri had completed an instrument panel redesign on our Cherokee Six more than 10 years prior. So, when we got on the phone together, it was like finding a long-lost friend.

George works mostly out of Zephyrhills, Florida (KZPH), but also has associations that allow him to operate out of Albert Whitted (KSPG) in St. Petersburg, which is where I left the Arrow a few months after I had flown in to discuss the details of the interior makeover. Knowing his schedule of nonstop clients, I was elated to get on the calendar.

It’s not often in life we meet special people, but George is one of them. Aside from his eye for design detail and sheer passion for a project, he has an incredible compassion for the human race, almost to a fault. His Lebanese background—being caught in the middle of a civil war as a child and then fleeing the conflict with his mother to Toronto—laid the foundation for his tenacity, perseverance, and work ethic. Being close enough to hear the sound of the propellers directing the missiles that exploded around him was part of his childhood. I can’t do his life story justice in this column because it will make your jaw drop.

Interestingly enough, George began his passion for aviation at 10 years old, observing the arrivals and memorizing the schedules of airlines flying into Beirut. The Boeing 747 was his favorite. To him, it was beautiful from every angle. I agree.

The product I was presented with after completion of the interior—including customized floor mats, extra seat pouches, rear-seat pillows, pump-up lumbar supports, and inlaid wood veneer—was spectacular. Our 51-year-old airplane has truly been transformed.

We can always find a rationale to justify the expense of our airplane improvements, but gaining another friend for life really makes it all worthwhile.

This column first appeared in the March 2024/Issue 946 of FLYING’s print edition.

Subscribe to Our Newsletter

Get the latest FLYING stories delivered directly to your inbox